Menu

Section (mm) : Ø5 - Ø50

Norm (EN 10278/h11)

Areas of Use

Machining - Automotive and Automotive Supply Industry Whiteware Supply Industry - Engine and Gear Systems Production Fasteners Production - Defense Industry - Pneumatic Systems Construction Industry - Energy Industry Agriculture Industry

Other Products

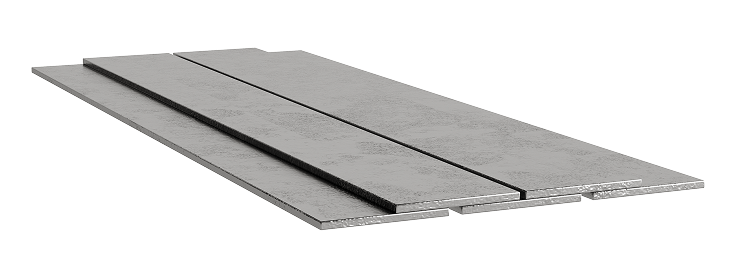

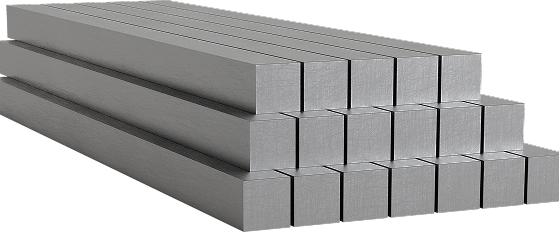

Our cold rolling facility, with an annual production capacity of 70,000 tons, quickly meets the demands of our customers with cold drawing processes from film to bar and from bar to bar. In our facility, we are constantly expanding our product range with in-line beveling, cut-to-length and precision tolerance production as well as peeling and grinding processes. We offer quality and various solutions by appealing to the market with flat, square, hexagonal and round shaft types in our production. We are strengthening our position in the sector with our understanding focusing on customer satisfaction and high quality standards.

Cold drawing is the process of reducing the cross-section of rolled steel by passing it through an open mold. The process is carried out at ambient temperature without extra heating. After the cold drawing process, surface sensitivity increases and elongation occurs in the length direction. After this plastic forming process, changes in mechanical values are achieved. The open mold, called sealer, with the help of the applied push and pull forces, eliminates surface defects such as scale and porosity, and provides a shiny and relatively smooth surface by scraping from the surface as well as cross-sectional contraction. In addition, the post-processing dimensional tolerances of the steels passed through these molds with precise tolerances are refined. This process can also improve mechanical properties. Hardness, Yield and Tensile Strengths can be increased by cold drawing process in varying amounts according to the forming ratio. Although cross-sections such as round, square, wedge, hexagonal are generally seen in cold drawing process, special design cross-section shapes can also be produced. Although it is generally seen that the cross-sectional shape of the shaft entering production and the shaft exiting production are the same, it is possible to change the cross-sectional shape in the cold drawing process with different mold designs.